#electric linear actuator india

Explore tagged Tumblr posts

Text

Choosing the Right Electric Linear Actuator for Your Indian Application

Electric linear actuators have become indispensable components in various industrial and automation applications. They offer precise and controlled linear motion, making them ideal for a wide range of tasks. However, when it comes to selecting the right electric linear actuator for your Indian application, several factors must be considered. In this comprehensive guide, we will explore the key aspects you should keep in mind to ensure you make the best choice.

Understanding Electric Linear Actuators

Before diving into the selection process, let's have a brief understanding of what electric linear actuators are and how they work.

What is an Electric Linear Actuator?

Electric linear actuators are devices that convert electrical energy into linear motion. They are commonly used to move or control objects in a straight line, making them suitable for applications such as opening and closing valves, lifting heavy loads, or adjusting the position of equipment.

Types of Electric Linear Actuators

Electric linear actuators come in various types, each designed for specific applications. It's crucial to choose the right type to ensure optimal performance and efficiency. Here are some common types:

Screw-Driven Actuators

Screw-driven actuators use a threaded rod and nut mechanism to convert rotary motion into linear motion. They are known for their precision and are suitable for applications requiring high accuracy, such as CNC machines and medical equipment.

Belt-Driven Actuators

Belt-driven actuators use a belt and pulley system to achieve linear motion. They are cost-effective and suitable for applications where speed is more critical than precision, like 3D printers and packaging machines.

Linear Servo Actuators

Linear servo actuators are highly precise and offer dynamic control. They are commonly used in robotics, automation, and aerospace applications that demand high-speed and accuracy.

Rodless Actuators

Rodless actuators are designed for space-saving applications. They offer a compact design and are ideal for situations with limited installation space.

Factors to Consider When Choosing an Electric Linear Actuator

Selecting the right electric linear actuator for your Indian application requires a thoughtful evaluation of several factors:

Load Capacity

Determine the maximum load your actuator will need to move. It's essential to choose an actuator that can handle the weight comfortably.

Speed and Stroke Length

Consider the required speed and stroke length for your application. Different actuators have varying speed capabilities and travel distances.

Environmental Conditions

Assess the environmental conditions in which the actuator will operate. Factors such as temperature, humidity, and exposure to dust or chemicals can impact the actuator's performance.

Mounting Options

Ensure that the actuator can be easily integrated into your existing system. Check the available mounting options and compatibility with your equipment.

Power Supply

Determine the power source for your actuator. Electric linear actuators typically operate on AC or DC power, so choose one that aligns with your facility's power supply.

Control and Feedback

Consider how you will control the actuator. Some actuators come with integrated feedback systems for precise positioning, while others may require external control systems.

Maintenance and Durability

Assess the maintenance requirements and overall durability of the actuator. Long-lasting, low-maintenance options are preferable for most applications.

Budget

Set a budget for your actuator. Keep in mind that while cost is important, it should not compromise performance and reliability.

Conclusion

Choosing the right electric linear actuator India application is a crucial decision that can significantly impact your project's success. By carefully evaluating factors like load capacity, speed, environmental conditions, and budget, you can make an informed choice that ensures optimal performance and efficiency.

#electric linear actuator India#electric linear actuator manufacturer India#electric linear actuator supplier India

0 notes

Text

Control Valves Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Control Valves Market – Industry Trends and Forecast to 2028

Global Control Valves Market, By Component (Valve Body, Actuators, Others), Material (Stainless Steel, Cast Iron, Alloy-Based, Cryogenic, Others), Type (Rotary Valves, Linear Valves), Operation (Hydraulic Control Valve, Pneumatic Control Valve, Electric Control Valve), Size (Less than 1”, Between 1” to 6”, Between 6” to 25”, Between 25” to 50”, More than 50”), End User (Oil and Gas, Energy and Power, Water and Wastewater Treatment, Food and Beverages, Chemicals, Pharmaceuticals, Construction, Pulp and Paper, Others) Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **Product Type:** The control valves market can be segmented based on product type into pneumatic control valves, hydraulic control valves, electric control valves, and others. Pneumatic control valves are widely used for applications requiring simple and reliable control mechanisms, while hydraulic control valves are preferred for high-pressure applications. Electric control valves are gaining popularity due to advancements in automation and remote control capabilities.

- **Application:** In terms of application, the market for control valves can be classified into oil and gas, water and wastewater treatment, power generation, chemicals, pharmaceuticals, and others. The oil and gas industry is a major end user of control valves, where they are essential for regulating flow, pressure, and temperature in various processes. Water and wastewater treatment plants also utilize control valves for precise control of water flow and treatment chemicals.

- **End-User Industry:** The market can also be segmented by end-user industry, including oil and gas, energy and power, water and wastewater, chemicals, pharmaceuticals, and others. The oil and gas sector dominates the demand for control valves due to the extensive use of valves in drilling operations, refineries, pipelines, and distribution networks. The energy and power industry follows closely, with control valves being integral to power generation plants for efficient operation and control.

**Market Players**

- **Emerson Electric Co.:** Emerson is a leading player in the global control valves market, offering a wide range of products catering to various industries. The company's innovative technologies and focus on customer needs have solidified its position in the market.

- **Flowserve Corporation:** Flowserve is another key player known for its comprehensive portfolio of control valves designed for critical applications in industries such as oil and gas, power generation, and water treatment. The company's global presence and dedication to quality make it a preferred choice for many customers.

- **Schneider Electric SE:** Schneider Electric is a prominent player that provides integrated solutions including control valves for industrial automation and processEmerson Electric Co., Flowserve Corporation, and Schneider Electric SE are key players in the global control valves market, each contributing significantly to the industry with their innovative solutions and strong market presence. Emerson's wide range of products tailored to various industries underscores its commitment to meeting diverse customer needs. The company's focus on technological advancements and customer-centric approach has enabled it to establish a strong foothold in the market, making it a preferred choice for many organizations across different sectors.

Flowserve Corporation is recognized for its comprehensive portfolio of control valves, specifically designed to address critical requirements in industries such as oil and gas, power generation, and water treatment. The company's global reach and unwavering dedication to quality and reliability have positioned it as a trusted partner for customers seeking high-performance control valve solutions. Flowserve's expertise in providing cutting-edge products for challenging applications further enhances its competitive edge in the market.

Schneider Electric SE stands out as a prominent player offering integrated solutions that encompass control valves for industrial automation and process applications. The company's emphasis on providing holistic solutions that enhance operational efficiency and productivity has earned it a strong reputation in the market. Schneider Electric's commitment to innovation and sustainability aligns with the evolving needs of industries worldwide, positioning it as a frontrunner in the control valves market.

The global control valves market continues to witness growth driven by factors such as increasing automation trends, focus on operational efficiency, and stringent regulations regarding process control and safety. The demand for control valves across various industries, including oil and gas, power generation, water and wastewater treatment, chemicals, and pharmaceuticals, underscores the significance of these components in optimizing industrial processes and ensuring smooth operations.

As industries increasingly adopt advanced technologies and digital solutions, the market for control valves is poised for further expansion. Companies like Emerson Electric Co., Flowserve Corporation, and Schneider Electric SE are at the forefront of driving innovation and setting industry standards in terms of product performance, reliability, and customer satisfaction. With a strong emphasis on research and development, these**Segments**

- **Product Type:** - Pneumatic control valves are preferred for simple and reliable applications. - Hydraulic control valves are suitable for high-pressure applications. - Electric control valves are gaining popularity due to automation advancements.

- **Application:** - Control valves are used across industries like oil and gas, water treatment, power generation, chemicals, and pharmaceuticals. - Essential for regulating flow, pressure, and temperature in various processes. - Water treatment plants rely on control valves for precise water flow control.

- **End-User Industry:** - Oil and gas, energy and power, water and wastewater, chemicals, pharmaceuticals are major users of control valves. - Oil and gas sector dominates demand due to extensive use in drilling, refining, and distribution. - Energy and power industry relies on control valves for efficient plant operation.

**Market Players**

- **Emerson Electric Co.:** - Offers a wide range of products catering to various industries. - Innovative technologies and customer focus strengthen market position.

- **Flowserve Corporation:** - Known for comprehensive control valve portfolio for critical applications. - Global presence and quality focus make it a preferred choice.

- **Schneider Electric SE:** - Provides integrated solutions including control valves for industrial automation. - Strong reputation for enhancing operational efficiency and productivity.

Global Control Valves Market drives growth through automation trends, operational efficiency focus, and stringent regulations. With rising adoption of technology

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Control Valves Market

Chapter 3: Regional analysis of the Global Control Valves Market industry

Chapter 4: Control Valves Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Control Valves Market report:

Detailed considerate of Control Valves Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Control Valves Market-leading players.

Control Valves Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Control Valves Market for forthcoming years.

Browse Trending Reports:

Thermal Imaging Cameras Market Baby Food Market Thin Film Encapsulation Market Paper Coating Materials Market Protein Engineering Market Psoriasis Treatment Market Whole Exome Sequencing Market Std Diagnostics Market Medication Delivery Systems Market Lane Keep Assist System Market Liquid Synthetic Rubber Market Mainframe Market Myxoid Round Cell Liposarcoma Drug Market Hematology Analyzer Market Low Differential Pressure Sensor Market Biofuel Enzyme Market Aroma Ingredients Market Coconut Water Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Linear Motion Products: Empowering Industrial Precision

In the modern industrial landscape, precision, efficiency, and reliability are key components that drive innovation and operational success. Industries ranging from automotive manufacturing to aerospace and automation heavily rely on equipment and machinery that ensure accuracy and smooth operation. One of the fundamental elements behind these systems is linear motion products. These high-performance components allow for smooth linear movement, contributing to everything from production lines to heavy-duty machine tools.

At Jai Krishna Bearing House, we take pride in being a trusted name in the industrial bearings sector, offering premium-quality linear motion products. Our company stands as one of India's leading importers and exporters of industrial bearings, including linear bearings and motion products, while also providing authorized dealer services across the country. With a strong reputation for delivering reliable solutions, Jai Krishna Bearing House has been an indispensable partner for industries looking to enhance precision and streamline their operations.

What Are Linear Motion Products?

Linear motion products consist of various components that facilitate controlled movement in a straight line. Unlike rotary motion, which follows a circular path, linear motion involves the back-and-forth movement along a straight trajectory. These components are widely used in applications where precision, low friction, and durability are critical.

Some of the most common linear motion products include:

Linear Bearings: These bearings are designed to support and guide movement in a straight line, reducing friction and wear. They come in several types, such as ball bearings and roller bearings, and can support loads in both horizontal and vertical directions.

Linear Guides: Also known as guide rails or linear rails, these are mechanical devices that provide smooth and accurate movement of an object along a straight path. Linear guides are essential in CNC machines and automation systems.

Ball Screws: Ball screws are used to convert rotary motion into linear motion with minimal friction. They are widely employed in high-precision applications like CNC machines, robots, and medical devices.

Linear Actuators: These are motorized devices that generate linear movement. They are often used in robotic systems, conveyors, and various automation tasks.

Linear Bushings: These are small, cylindrical components that guide linear shafts in their movement, minimizing friction. Linear bushings are used in equipment where accuracy and smooth operation are essential.

Linear Motors: A type of electric motor that produces linear motion directly without the need for mechanical conversion from rotary motion. These are used in applications requiring high-speed, precise movement.

At Jai Krishna Bearing House we offer a wide range of linear motion products designed to meet the demanding requirements of industries seeking high performance and efficiency.

Importance of Linear Motion Products in Modern Industry

Linear motion products are integral to the success of numerous industrial operations. They are used in applications where accuracy, speed, and durability are essential to maintaining productivity and ensuring the quality of end products. Here's how linear motion components enhance industrial performance:

Precision and Accuracy

Linear motion products are critical in environments where even the smallest deviation can lead to errors and inefficiencies. In the manufacturing and automation industries, where high accuracy is required, linear motion components ensure smooth and precise operations. For example, CNC machines rely on ball screws and linear guides to produce exact cuts and movements, ensuring that components are manufactured with exacting standards.

Enhanced Durability and Reliability

Industrial equipment often operates under high-stress conditions, where wear and tear can cause significant downtime and costly repairs. Linear motion products are designed to handle extreme situations, ensuring longer lifespans and reduced maintenance costs. Components such as linear bearings and actuators are engineered to withstand heavy loads, high speeds, and harsh environments.

Increased Efficiency

Linear motion products contribute to the efficiency of industrial systems by reducing friction and wear, ensuring smooth operations. Whether it's a conveyor belt in a manufacturing plant or a robotic arm in an assembly line, linear motion components minimize energy consumption and maximize the overall efficiency of machines. This results in faster production times and optimized workflows.

Flexibility in Application

One of the biggest advantages of linear motion products is their versatility. From medical equipment that requires delicate movements to heavy machinery in construction, these components can be adapted for use in various industries. They are used in sectors like automotive, electronics, aerospace, food and beverage processing, and material handling, to name a few.

Jai Krishna Bearing House: Your Trusted Partner for Linear Motion Solutions

At Jai Krishna Bearing House, we are dedicated to offering the highest quality linear motion products that cater to the specific needs of industries across India and beyond. As an industrial bearings importer and exporter, our commitment to delivering premium solutions has helped us establish a strong reputation for reliability and performance. Here’s what sets us apart:

Expertise in Industrial Bearings: With years of experience in the field, we provide unparalleled knowledge and expertise in industrial bearings, including linear motion components. Our team of professionals understands the unique challenges faced by various industries and offers tailor-made solutions to meet those needs.

Comprehensive Product Range: From linear bearings and guides to actuators and ball screws, we offer a comprehensive range of linear motion products designed to enhance precision and durability in industrial applications.

Authorized Dealer Services: As an authorized dealer, we ensure that all our products are sourced from reputable manufacturers, guaranteeing quality and performance. Our strong partnerships with global brands allow us to offer competitive prices without compromising on reliability.

Global Reach: We export our products to various international markets, meeting the stringent quality standards demanded by industries worldwide. Our global reach enables us to stay at the forefront of innovation and offer our clients the best solutions available.

Conclusion

In today's competitive industrial environment, precision, durability, and efficiency are non-negotiable. Linear motion products play an essential role in ensuring that industries operate with the highest standards of performance and reliability. At Jai Krishna Bearing House, we are proud to be a trusted supplier of these critical components, helping industries across India and the world achieve their goals through our top-notch solutions. Jai Krishna Bearing House linear bearings, guides, or other motion products, our extensive product range and expertise are here to meet your needs and drive your operations forward

0 notes

Text

How to Use a Control Valve Sizing Calculator Effectively?

To guarantee correct results, there are a few essential procedures to properly using a control valve-sizing calculator. First, compile the essential information, including the fluid's properties, pressure drop, flow rate, and obligatory valve characteristics. Make sure the units in the calculator match as you enter these figures. Next, depending on your application—whether it's linear or equal percentage—choose the right kind of valve and size technique. Examine the valve size, Cv (flow coefficient), and other pertinent values that were computed. In order to improve performance, compare the sizing to the system requirements and take into account variables like valve authority and operating conditions. Maintaining precision in valve selection and operation requires regular input updates.

How to Locate Trustworthy Mumbai Valve Dealers

Finding approved distributors who provide authentic goods and dependable service is essential while searching for Audco valves dealers in Mumbai. Due to the high caliber and longevity of Audco valves, selecting dealers with a solid track record and reputation in the business is crucial. To determine their dependability, look for qualifications and client testimonials.

KSB valves dealers in Mumbai also make the availability of an extensive selection of industrial valves renowned for their dependability and effectiveness possible. Choosing an authorized KSB dealer guarantees that the items you receive satisfy technical specifications and international standards, regardless of whether you need specialized control valves, gate valves, or butterfly valves.

Wholesalers of Top Valve Brands

The forbes marshall valves distributors, which are renowned for their performance and creativity, are essential. A wide variety of valves, from steam to fluid control systems, is available from Forbes Marshall for use in a variety of industrial applications. You can be sure you'll get professional guidance and after-sales assistance by selecting a reliable distributor.

With a wide range of valves and fittings, leader valves dealers in Mumbai serve both the commercial and residential markets. Leader valves are appreciated for their affordability and reliability in both industrial and plumbing requests. Mumbai dealers provide easy access as well as local assistance for installation and upkeep.

Mumbai-Based Providers of Specialized Valve

India's leading dealers of valves to the power, oil, and gas businesses are the BHEL valves dealers in Mumbai. For large-scale industrial projects, Bharat Heavy Electricals Limited (BHEL) valves are essential components, necessitating dealers who can offer timely delivery and technical experience.

A large range of valves made by famous engineering giant Larsen & Toubro are obtainable from L&T valves dealers in Mumbai. L&T valves are preferred in industries like oil and gas, petrochemicals, and power group because of their standing for accuracy and performance. A project's criteria and industry standards are met when authorized dealers are chosen.

India's Auma Actuator Dealers

Essential components for valve automation systems are supplied by Auma actuator dealers in India. Because of their cutting-edge technology and reputation for dependability, Auma actuators are ideal for demanding applications across a range of sectors. When choosing the ideal actuator for your valve system, authorized dealers provide technical knowledge and assistance.

Effective Application of Calculators for Control Valve Sizing

For precise selection of the appropriate valve size and specifications for your application, a control valve sizing calculator is a must. These calculators combine variables like fluid qualities, flow rates, pressure drops, and valve features to calculate the ideal valve size and Cv value. Using the calculator guarantees efficiency and dependability in system performance when sizing a valve for pressure regulation or flow control.

Industries in Mumbai and around India may guarantee dependable and effective operation of their valve systems by employing the knowledge of authorized dealers and cutting-edge equipment like control valve sizing calculators. The secret to maximizing performance and longevity of valves, whether you're sourcing Audco, KSB, Forbes Marshall, Leader, BHEL, or L&T, is to use precise sizing tools and select reliable dealers.

0 notes

Text

Actuators Market: Forthcoming Trends and Share Analysis by 2032

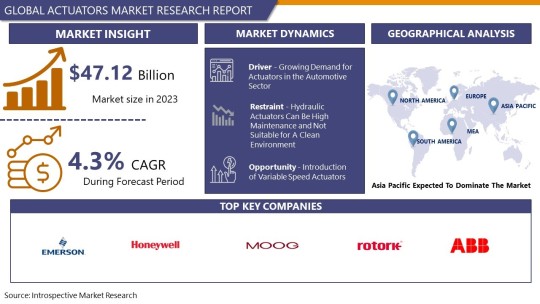

Global Actuators Market Size Was Valued at USD 47.12 Billion In 2023 And Is Projected to Reach USD 68.83 Billion By 2032, Growing at a CAGR of 4.3% From 2024 To 2032.

Actuators are machines that transform energy into motion; its main applications are in the control and movement of systems and processes. An external power source—usually electrical electricity, hydraulic fluid pressure, or pneumatic pressure—powers actuators and transforms that power into motion. Actuators are capable of two basic movements: rotation and linear motion. Different types, sizes, and power combinations are available for them based on the intended purposes. Due to widespread use in a number of industries, including material handling, robotics, food and beverage manufacturing, window automation, agricultural machinery, solar panel operation, cutting equipment, valve operation, non-industrial applications, and automotive and mechanical machinery, the actuator market has expanded significantly. The actuators market has seen strong sales over the past ten years due to the increasing demand from these business verticals, as evolution and the requirement for power-hungry machinery and automobiles have increased dramatically.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/4048

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Actuators Market include:

Honeywell International Inc.

Siemens AG

Emerson Electric Co.

Schneider Electric SE

ABB Ltd.

Rotork plc

Parker Hannifin Corporation

SMC Corporation

Festo AG & Co. KG

Johnson Controls International plc

Belimo Holding AG

Danfoss A/S

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Actuators Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/4048

Segmentation of Actuators Market:

By Type

Linear Actuator

Rotary Actuator

By System

Electrical

Pneumatic

Hydraulic

Others

By End-Users

Oil & Gas

Pharmaceutical & Healthcare

Automotive

Aerospace & Defense

Marine

Others

An in-depth study of the Actuators industry for the years 2023–2030 is provided in the latest research. North America, Europe, Asia-Pacific, South America, the Middle East, and Africa are only some of the regions included in the report's segmented and regional analyses. The research also includes key insights including market trends and potential opportunities based on these major insights. All these quantitative data, such as market size and revenue forecasts, and qualitative data, such as customers' values, needs, and buying inclinations, are integral parts of any thorough market analysis.

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Key Benefits of Actuators Market Research:

Research Report covers the Industry drivers, restraints, opportunities and challenges

Competitive landscape & strategies of leading key players

Potential & niche segments and regional analysis exhibiting promising growth covered in the study

Recent industry trends and market developments

Research provides historical, current, and projected market size & share, in terms of value

Market intelligence to enable effective decision making

Growth opportunities and trend analysis

Covid-19 Impact analysis and analysis to Actuators market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=4048

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assist our clients grow and have a successful impact on the market. Our team at IMR is ready to assist our clients flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, specialized in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1 773 382 1049

Email: [email protected]

#Actuators#Actuators Market#Actuators Market Size#Actuators Market Share#Actuators Market Growth#Actuators Market Trend#Actuators Market segment#Actuators Market Opportunity#Actuators Market Analysis 2024

0 notes

Text

Electric Actuator Manufacturers in India | CKD | SEIMITSU

CKD offers electric actuators in different types and configurations to meet the diverse needs of its customers. These actuators are designed to provide precise control over linear or rotary motion and can be integrated into automated systems for tasks such as valve control, positioning, and other motion control applications. There are different types of electric actuators available, including linear actuators, rotary actuators, and multi-axis actuators, each designed to fulfill specific motion requirements. Linear actuators produce linear motion (straight line movement), while rotary actuators produce rotational motion (circular movement). Multi-axis actuators combine multiple linear or rotary actuators to achieve motion in multiple directions or axes. To know more please visit https://www.seimitsu.in/CKD-electric-actuator-supplier-in-pune.html

#ckdpneumatics#ckd#electricactuator#servodriveactuator#servomotor#supplier#seimitsufactoryautomation

0 notes

Text

Aircraft Seat Actuation Systems Market to Witness Steady Demand from Business and First Class Segments

The market is expected to grow at a steady pace driven by increasing air passenger traffic globally. Rising disposable incomes are enabling more people to opt for air travel.

Linear actuators dominate current installations as most seat adjustment functions are linear in nature. However, rotary actuators could gain share in the future as seating designs evolve.

𝐂𝐥𝐢𝐜𝐤 𝐧𝐨𝐰 𝐭𝐨 𝐞𝐱𝐩𝐥𝐨𝐫𝐞 𝐦𝐨𝐫𝐞 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬: https://www.transparencymarketresearch.com/aircraft-seat-actuation-systems-market.html

Business and first class segments account for a major portion of revenues due to higher unit prices and more advanced features in premium seats. Economy plus is the fastest growing segment.

Europe is the largest regional market currently due to strong presence of aircraft OEMs like Airbus. However, Asia Pacific is poised to be the new growth engine led by China and India.

Key players are focusing on developing lighter, more compact actuators with lower noise levels. There is also a push for intelligent systems with flexible designs.

M&A activity can be expected to intensify as major companies look to enhance their seating technology portfolio through acquisitions.

Adoption of electric actuation systems over hydraulic/pneumatic types will be a key trend, driven by the need for improved fuel efficiency in aircraft.

Innovation in seating ergonomics, cabin comfort systems and passenger experience technologies will likely drive further opportunities in this market.

#AircraftSeatingTech#PremiumCabinTravel#IntelligentActuation#AviationGrowthRegions#AerospaceMandA#ModularAircraftDesign#ConnectedAircraft#SustainableAviation#MilitaryAerospaceTech#FutureOfFlight

0 notes

Text

How does a Hydraulic Power Pack Machine Works?

What is Hydraulic Power Pack Machine?

A hydraulic power pack machine, often referred to simply as a hydraulic power pack or hydraulic power unit (HPU), is a compact device used to generate hydraulic power for various machinery and equipment. It plays a crucial role in powering hydraulic systems, which are widely used in industries for applications such as lifting, pressing, bending, cutting, and more.

Here's how a typical hydraulic power pack Machine works:

Prime Mover: The power pack is typically driven by an electric motor or an internal combustion engine (diesel or gasoline). The prime mover provides the mechanical energy required to run the hydraulic system.

Reservoir: The power pack has a hydraulic fluid reservoir (often a tank) that stores hydraulic oil. This oil serves as the working fluid for the hydraulic system.

Hydraulic Pump: The prime mover drives a hydraulic pump. The pump is responsible for drawing hydraulic oil from the reservoir and pressurizing it. The pressurized oil is then delivered to the rest of the hydraulic system.

Directional Control Valves: A hydraulic power pack is equipped with directional control valves. These valves control the direction of hydraulic fluid flow in the system. By actuating these valves, you can determine which hydraulic components (such as cylinders or motors) will receive pressurized oil and in which direction.

Pressure Relief Valve: For safety and to prevent system damage from excessive pressure, a pressure relief valve is usually included in the power pack. It releases excess pressure back into the reservoir if the pressure in the system becomes too high.

Hydraulic Actuators: The high-pressure hydraulic oil from the power pack is routed to hydraulic actuators, which can include hydraulic cylinders, hydraulic motors, or other hydraulic devices. These actuators convert the hydraulic energy back into mechanical work, whether it's linear motion in the case of cylinders or rotational motion in the case of motors.

Return Flow: After the hydraulic fluid has done its work, it returns to the reservoir, completing the hydraulic circuit. The cycle can repeat as needed based on the control of the directional valves and the operation of the hydraulic actuators.

Filtration and Cooling: Most hydraulic power packs include filtration systems to remove contaminants from the hydraulic oil, ensuring the system's reliability. They may also include cooling systems (such as heat exchangers or fans) to dissipate heat generated during operation.

The specific operation of a hydraulic power pack can vary depending on the application, whether it's powering a hydraulic press, a hydraulic lift, a conveyor system, or any other hydraulic machinery. The key is that it generates and controls high-pressure hydraulic fluid to perform work in various industrial and mobile applications.

Best Hydraulic Power Pack Machine Manufacturer in India

If you are looking for the best Hydraulic Power Pack Machine manufacturer in India, look no further than Radhey Krishan Industries. With a proven track record of excellence, Radhey Krishan Industries is a leading manufacturer and supplier of hydraulic power pack machines in India. Their commitment to quality, innovative design, and customer satisfaction sets them apart in the hydraulic machinery industry. Whether you require hydraulic power packs for industrial, commercial, or specialized applications, Radhey Krishan Industries offers reliable and efficient solutions to meet your specific needs. Trust in their expertise to deliver top-notch hydraulic power pack machines that ensure optimal performance and power your hydraulic systems effectively.

For any type of queries, please contact us!

Website - www.radheykrishanindustries.com

Email - [email protected] Contact - +91-7836842828

#best hydraulic press machine#hydraulic power pack machine manufacturer#hydraulic power pack machine manufacturer in India#hydraulic power pack machine Supplier#hydraulic power pack machine Supplier in India#best hydraulic power pack machine manufacturer in India

1 note

·

View note

Text

A Comprehensive Guide to Electric Linear Actuator Applications in India

Electric linear actuators have revolutionized the way we interact with machines and devices, offering precise and controlled linear motion. These versatile devices find a wide range of applications across various industries in India. In this comprehensive guide, we'll delve into the diverse applications of electric linear actuators, highlighting their importance and impact on different sectors.

Electric linear actuators are devices designed to convert rotational motion into linear motion, allowing for precise control over positioning. They consist of an electric motor, a lead screw, and a nut. When the motor rotates, the lead screw moves through the nut, driving linear movement.

Advantages of Electric Linear Actuators

Electric linear actuators offer several advantages over other actuation methods, such as hydraulic or pneumatic systems. They are quieter, more precise, and environmentally friendly due to their lack of fluid leakage.

Industrial Automation

Enhancing Manufacturing Processes

In the manufacturing sector, electric linear actuators play a crucial role in automating production lines. They ensure precise positioning of components, reducing errors and enhancing overall efficiency.

Conveyor Systems Optimization

Electric linear actuators are used to adjust the height and angle of conveyor systems, facilitating smooth material transfer and reducing the risk of jams.

Robotic Assembly Lines

Robots equipped with electric linear actuators can perform intricate tasks with high accuracy, making them indispensable in modern assembly lines.

Healthcare and Medical Sector

Hospital Beds and Patient Lifts

Electric linear actuators enable the adjustment of hospital bed positions, providing comfort to patients and assisting caregivers in providing better care.

Rehabilitation Equipment

In rehabilitation devices, such as wheelchairs and mobility aids, electric linear actuators enable adjustable seating positions, aiding patients in their recovery journey.

Surgical Robots

Electric linear actuators are integrated into surgical robots, granting surgeons precise control over robotic arms during minimally invasive procedures.

Agriculture and Farming

Automated Irrigation Systems

In agriculture, electric linear actuators control valves in automated irrigation systems, ensuring optimal water distribution for crops.

Ventilation Control in Greenhouses

Electric linear actuators regulate window openings and ventilation systems in greenhouses, maintaining optimal growing conditions.

Feeding Systems for Livestock

Linear actuators automated feeding systems in livestock farms, ensuring consistent and timely nutrition for animals.

Automotive and Transportation

Electric Vehicle Charging Infrastructure

Electric linear actuators assist in positioning charging connectors in electric vehicle charging stations, optimizing user experience.

Adjustable Car Seats and Mirrors

Linear actuators in cars enable customizable seating positions and mirror adjustments, enhancing driver comfort and safety.

Cargo Handling in Logistics

In logistics, electric linear actuators power conveyor belts and lifting mechanisms, streamlining cargo loading and unloading processes.

Aerospace and Defense

Aircraft Flap Control

Electric linear actuators control aircraft flaps, contributing to aerodynamic adjustments and safe takeoffs and landings.

Satellite Dish Alignment

In the aerospace sector, linear actuators ensure precise alignment of satellite dishes for uninterrupted communication.

Surveillance Systems

Electric linear actuators are used in surveillance equipment to control camera movement, covering wider areas with enhanced flexibility.

Energy and Renewables

Solar Panel Tracking

Linear actuators track the movement of solar panels, allowing them to follow the sun's path and maximize energy generation.

Wind Turbine Pitch Control

Electric linear actuators adjust the pitch angle of wind turbine blades to optimize energy capture based on wind conditions.

Hydroelectric Dam Mechanisms

In hydroelectric power generation, linear actuators control dam gates and mechanisms, managing water flow and electricity production.

Home and Furniture

Smart Home Window Automation

Electric linear actuators automate window opening and closing in smart homes, promoting energy efficiency and convenience.

TV Lift Mechanisms

Linear actuators lift and lower TVs from furniture, saving space and providing unique viewing experiences.

Adjustable Furniture

Electric linear actuators are integrated into furniture pieces like desks and beds, allowing users to adjust heights and positions.

Conclusion

Electric linear actuators have found diverse applications in India across industries, revolutionizing automation, precision control, and comfort. Their role in industrial processes, healthcare, agriculture, transportation, aerospace, energy, and even everyday homes is undeniable. As technology continues to advance, electric linear actuator India will likely continue to drive innovation and efficiency across sectors.

#electric linear actuator india#electric linear actuator manufacturer#electric linear actuator supplier

0 notes

Text

Pressure Relief Valves In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Pressure Relief Valves Market Research, 2031

The global pressure relief valves market size was valued at $4.4 billion in 2021, and is projected to reach $7 billion by 2031, growing at a CAGR of 4.6% from 2022 to 2031.Pressure relief valve (PRV) is also called as a relief valve. Pressure vessels and other equipment are protected by pressure relief valve from being subjected to pressures that exceed their design limits. The valve is used to control or limit the pressure built inside the equipment which may cause equipment or instrument failure, or fire. The pressure is relieved by allowing the pressurized fluid to flow from an auxiliary passage out of the system.

Pressure relief valve are used in the oil & gas industry for drilling and workover operations, which, in turn, increase demand for pressure relief valve, and is anticipated to boost growth of the pressure relief valve market. According to a report on North America Midstream Infrastructure through 2035 published in June 2018 by ICF International Inc., total investments in oil & gas infrastructure are projected to range between $685 billion and $895 billion from 2018 to 2035. In addition, pharmaceuticals and food & beverages industries are largely saturated in developing countries including European Union, such as the U.S. and China. Pressure relief valve have an important role in manufacturing of different types of medical devices and support key players to give opportunity during this pandemic situation. For instance, according to the India Brand Equity Foundation (IBEF), the food & beverage processing industry has emerged as a high-profit and high-growth sector, owing to its immense growth potential. Moreover, rise in number of industrial infrastructure projects in developing countries is driving the demand of pressure relief valves market. For instance, the government of China spent $10 billion on a new oil & gas refinery project, Guangdong refinery, which is expected to be completed by March 2022. Such instances are expected to drive the growth of the market. There are many domestic manufacturers present in places, which is expected to hamper growth of the pressure relief valve market. Domestic manufacturers provide pressure relief valve ranging from $100 to $200. However, key players offer pressure relief valve ranging from $100 to $2500. Hence, customer focuses more on adopting pressure relief valve from domestic manufacturers, which, in turn, hinders the pressure relief valves industry growth.

The global pressure relief valve market is segmented on the basis of valve type, pressure, end user, and region. Based on valve type, the market is divided into spring loaded, pilot loaded, dead weight and p and t actuated. Based on pressure, the market is divided into low, medium and high. Based on end user industry, the market is divided into oil & gas, chemical, power generation, food & beverage, manufacturing and water & wastewater.

COMPETITION ANALYSIS

The major players profiled in the pressure relief valve market include AGF Manufacturing, Inc., Alfa Laval, Curtis-Wright Corp, Emerson Electric Co., General Electric, Goetze KG Armaturen, IMI PLC, Mercury Manufacturing Company Limited, The Weir Group PLC, and Watts Water Technology, Inc.

Major companies in the market have adopted acquisition and product launch as their key developmental strategies to offer better products and services to customers in the pressure relief valve market.

Some examples of acquisition in the market

In February 2020, Curtiss-Wright Corporation, a leading provider of pressure safety and release valves, has acquired Dyna-Flo, a well-known designer and manufacturer of linear and rotary control valves, isolation valves, actuators, and level and pressure control systems for the chemical, petrochemical, and oil and gas markets, for $62 million. The acquired business will operate within commercial/industrial segment of Curtiss-Wright.

Some examples of product launch in the market

In December 2022, Emerson has launched two new-to-the-world technologies for the Crosby J-Series pressure relief valve (PRV) product line.

In April 2022, Lamot Valve & Arrestor has launched its new product: the Model L11E Weight-Loaded Pressure Relief Valve. The valve includes an option to add calibrated weights in 0.5 using increments, giving the operator the flexibility to adjust the set pressure of this valve from the top of the tank and eliminating the need to remove and retest in the shop on a test stand. It can be used as a stand-alone vent to the atmosphere pressure relief valve or can be used in addition to existing pressure relief valves to add additional flow capacity.

In December 2020, Weir Oil & Gas has launched latch back pressure valve system to increase safety, reliability of drill- thru operations.

In December 2020, Consolidated, a Baker Hughes subsidiary, has launched its new 1900 series dual media (DM) spring-loaded safety relief valve (SRV) with patented trim. The new series is designed to perform on both liquid and gas media and has dual certification (liquid and gas) nameplate capacity stamping in accordance with ASME (American Society of Mechanical Engineers) and BPVC (Boiler and Pressure Vessel) Code Case 2787. The 1900 DM series is the first and only spring-loaded safety relief valve in the industry that is ‘dual certified.’ Dual certified means the valve is both vapor/gas and liquid flow certified without making any modifications or adjustments to the relief device when switching fluids during the flow testing.

In November 2020, Danfoss has launched its new 65bar safety valve, SFA 10H, that offers reduced capacity, high reliability, and high-pressure for applications with CO2 and synthetic oils. The design and manufacturing of this product focuses on preventing leaks, providing perfect reseating after release, and keeping a stable set pressure over time.

In April 2020, Baker and Hughes has launched the 2900 series gen II pilot pressure relief valve (PRV). This innovative product has a full-nozzle main valve that easily threads in and out to save maintenance expenses while protecting the main valve body from corrosive service under normal operating circumstances. In May 2019, Weir Oil & Gas has launched SPM SafeEdge ARC for Remote Setting and Digital Control of Relief Valves.

Full Report With TOC:-https://www.alliedmarketresearch.com/pressure-relief-valves-market-A16110#:~:text=The%20global%20pressure%20relief%20valves,called%20as%20a%20relief%20valve.

0 notes

Text

Control Valves Market Size, Share, Trends, Growth and Competitive Outlook

"Global Control Valves Market – Industry Trends and Forecast to 2028

Global Control Valves Market, By Component (Valve Body, Actuators, Others), Material (Stainless Steel, Cast Iron, Alloy-Based, Cryogenic, Others), Type (Rotary Valves, Linear Valves), Operation (Hydraulic Control Valve, Pneumatic Control Valve, Electric Control Valve), Size (Less than 1”, Between 1” to 6”, Between 6” to 25”, Between 25” to 50”, More than 50”), End User (Oil and Gas, Energy and Power, Water and Wastewater Treatment, Food and Beverages, Chemicals, Pharmaceuticals, Construction, Pulp and Paper, Others) Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- Based on type, the control valves market can be segmented into pneumatic control valves, hydraulic control valves, electric control valves, and others. Pneumatic control valves are widely used for various industrial applications due to their reliability and cost-effectiveness. Hydraulic control valves offer precise control in critical processes, making them a preferred choice in industries such as oil and gas. Electric control valves are gaining popularity due to their ease of integration with digital control systems, providing advanced functionalities and automation capabilities.

- By application, the control valves market can be categorized into oil & gas, water and wastewater treatment, power generation, chemicals, food and beverage, and others. The oil & gas sector is a major end-user of control valves, utilizing them for flow and pressure control in drilling operations, refining processes, and pipeline transportation. Water and wastewater treatment plants rely on control valves for regulating the flow of water, chemicals, and sludge in treatment processes. In power generation plants, control valves play a crucial role in steam and gas flow control, contributing to efficient operations and power generation.

- Geographically, the control valves market is divided into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific holds a significant market share in the control valves industry, driven by rapid industrialization, infrastructure development, and increasing investments in sectors such as oil & gas, power generation, and chemicals. North America and Europe also have substantial market presence, fueled by advanced technologies, stringent regulations, and focus on energy efficiency and environmental sustainability.

**Market Players**

- Some of the key players in the control valves market include Emerson Electric Co., Flowserve Corporation, Honeywell International Inc., IMI PLC, Siemens AG, Schlumberger Limited, AVK Holding A/S, Burkert Fluid Control Systems, Crane Co., and Curtiss-Wright Corporation. These companies are at the forefront of innovation, offering a wide range of control valve solutions to meet the diverse needs of industries worldwide. TheyThe control valves market is experiencing steady growth and evolution driven by technological advancements, industrial automation, and the increasing demand for efficient process control solutions across various industries. The segmentation of the market based on type highlights the different technologies and mechanisms used in control valves, catering to specific industry requirements. Pneumatic control valves, being reliable and cost-effective, find extensive use in industrial applications where precision control is not a critical factor. In contrast, hydraulic control valves offer precise control needed in critical processes within industries like oil and gas. Electric control valves are gaining traction due to their compatibility with digital control systems, enabling advanced functionalities and automation capabilities, which are increasingly valued in modern industrial settings.

Regarding applications, the market segmentation reflects the diverse industries benefiting from control valves' contributions to operational efficiency and process control. The oil & gas sector stands out as a significant end-user of control valves, leveraging them in various operations such as drilling, refining, and pipeline transportation for flow and pressure regulation. Water and wastewater treatment plants rely on control valves to regulate the flow of water, chemicals, and other substances throughout the treatment processes, thereby ensuring optimal treatment efficiency. In power generation, control valves play a crucial role in managing steam and gas flow, contributing to enhanced operational performance and power generation efficiency.

Geographically, the control valves market exhibits a global presence, with key regions such as Asia Pacific, North America, and Europe leading in market share. Asia Pacific's dominance is attributed to rapid industrialization, infrastructural development, and increasing investments in sectors like oil & gas, power generation, and chemicals. North America and Europe also hold substantial market shares, driven by technological innovation, stringent regulatory frameworks promoting energy efficiency and sustainability, and a focus on advanced manufacturing practices.

The market players in the control valves industry, such as Emerson Electric Co., Flowserve Corporation, Honeywell International Inc., and Siemens AG, among others, are pivotal in driving market growth through continuous innovation and the development of tailored control valve solutions for diverse industry needs. These companies**Segments**

- Global Control Valves Market, By Component (Valve Body, Actuators, Others), Material (Stainless Steel, Cast Iron, Alloy-Based, Cryogenic, Others), Type (Rotary Valves, Linear Valves), Operation (Hydraulic Control Valve, Pneumatic Control Valve, Electric Control Valve), Size (Less than 1"", Between 1"" to 6"", Between 6"" to 25"", Between 25"" to 50"", More than 50""), End User (Oil and Gas, Energy and Power, Water and Wastewater Treatment, Food and Beverages, Chemicals, Pharmaceuticals, Construction, Pulp and Paper, Others) Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Market analysis reveals a robust and expanding control valves market, characterized by various segments that capture the diverse applications and regional preferences of industry players. The division based on type showcases the technological diversity within the market, catering to specific industrial needs. Pneumatic control valves offer a reliable and cost-effective solution for industries

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Control Valves Market

Chapter 3: Regional analysis of the Global Control Valves Market industry

Chapter 4: Control Valves Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Control Valves Market report:

Detailed considerate of Control Valves Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Control Valves Market-leading players.

Control Valves Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Control Valves Market for forthcoming years.

Browse Trending Reports:

Thermal Imaging Cameras Market Baby Food Market Thin Film Encapsulation Market Paper Coating Materials Market Protein Engineering Market Psoriasis Treatment Market Whole Exome Sequencing Market Std Diagnostics Market Medication Delivery Systems Market Lane Keep Assist System Market Liquid Synthetic Rubber Market Mainframe Market Myxoid Round Cell Liposarcoma Drug Market Hematology Analyzer Market Low Differential Pressure Sensor Market Biofuel Enzyme Market Aroma Ingredients Market Coconut Water Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Electro Pneumatic Positioner Market Size, Share and Price Analysis.

The electro-pneumatic positioner market refers to the industry that deals with the manufacturing, distribution, and sale of electro-pneumatic positioners.

Electro-pneumatic positioners are devices used in industrial processes to accurately control the position of valves and actuators. These positioners receive an electrical signal from a controller or a control system and convert it into a pneumatic signal, which is then used to position the valve or actuator. They play a crucial role in various industries, including oil and gas, chemical, power generation, water and wastewater treatment, and manufacturing.

The market for electro-pneumatic positioners has been witnessing growth due to several factors. The increasing demand for process automation in industries, the need for accurate control and positioning of valves, and the growing adoption of Industrial Internet of Things (IIoT) and digitalization are some of the key drivers for this market.

Enquiry now:- https://www.alliedmarketresearch.com/request-toc-and-sample/4452

The electro-pneumatic positioner market is highly competitive and consists of several manufacturers and suppliers. Companies in this market offer a wide range of products with different features and specifications to cater to the diverse requirements of industries. Some of the prominent players in the market include ABB Ltd., Emerson Electric Co., Siemens AG, Schneider Electric SE, and Yokogawa Electric Corporation.

The market is also influenced by technological advancements. Manufacturers are focusing on developing advanced electro-pneumatic positioners with improved accuracy, reliability, and communication capabilities. Integration of smart features such as diagnostics, predictive maintenance, and remote monitoring is becoming increasingly common.

Enquiry for price :- https://www.alliedmarketresearch.com/electro-pneumatic-positioner-market/purchase-options

Geographically, the market for electro-pneumatic positioners is spread across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. The Asia Pacific region is expected to witness significant growth in the market due to the rapid industrialization and infrastructure development in countries like China and India.

The global electro pneumatic positioner market is segmented based on type, end-user industry, and geography. By type, the market is divided into linear positioner and rotary positioner. By end-user industry, the market is divided into oil & gas, power generation, chemical, metal & mining, and others. Based on region, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Contact for Customization :- https://www.alliedmarketresearch.com/request-for-customization/4452

At present, the global electro pneumatic positioner market in dominated some key players namely: Actuant Corporation, Danaher Corporation, Emerson Electric Co., Hilti Corporation, Hitachi Koki Ltd., Makita Corporation, Robert Bosch GmbH, SKF, Stanley Black & Decker, Inc, and Techtronic Industries.

In summary, the electro-pneumatic positioner market is a dynamic and growing industry driven by the need for precise valve and actuator control in various industrial processes. The market is competitive, with a focus on technological advancements and the integration of smart features.

About Us: Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Contact Us: David Correa 5933 NE Win Sivers Drive #205, Portland, OR 97220 United States USA/Canada (Toll Free): +1–800–792–5285, +1–503–894–6022 UK: +44–845–528–1300 Hong Kong: +852–301–84916 India (Pune): +91–20–66346060 Fax: +1(855)550–5975 [email protected] Web: https://www.alliedmarketresearch.com/reports-store/construction-and-manufacturing

0 notes

Text

Revolutionize Your Engineering Projects with the Best Rotary Actuator in India

In the fast-paced world of engineering, precision, and efficiency are paramount. Whether working on robotics, manufacturing, aerospace, or any other engineering project, having the right equipment can make all the difference. One such essential component is the rotary actuator. This article will explore how the best rotary actuator India can revolutionize your engineering projects, providing unparalleled control, versatility, and reliability.

What is a Rotary Actuator?

A rotary actuator is a mechanical device that converts rotational motion into linear motion or vice versa. It is commonly used in various engineering applications requiring precise positioning and control. A rotary actuator's basic functioning involves converting fluid pressure or electrical energy into mechanical torque, enabling the actuator to rotate or move.

Types of Rotary Actuators

There are three main types of rotary actuators: pneumatic, hydraulic, and electric. Pneumatic rotary actuators use compressed air to generate the necessary force for rotation. Hydraulic rotary actuators utilize hydraulic fluid under pressure to achieve rotational movement. On the other hand, electric rotary actuators employ electric motors to convert electrical energy into rotational force.

Advantages of Using Rotary Actuators in Engineering Projects

Using rotary actuators in engineering projects offers numerous advantages that greatly enhance performance and productivity. Firstly, rotary actuators provide increased precision and control, allowing for precise positioning and movement. This is crucial in applications where accuracy is paramount.

Additionally, rotary actuators are known for their compact design and space efficiency. They can be easily integrated into existing systems without occupying excessive space, making them ideal for projects with limited room.

Moreover, rotary actuators are highly versatile and adaptable. They can be customized to meet specific project requirements, including torque capacity, speed, and rotation angle. This flexibility allows engineers to tailor the actuator's performance to their needs.

Key Features to Consider When Choosing a Rotary Actuator

When selecting a rotary actuator for your engineering project, several key features should be considered. These include torque capacity, speed and rotation angle, mounting options, and environmental considerations.

The torque capacity of the actuator determines the maximum force it can exert. It is crucial to choose an actuator with sufficient torque to meet the requirements of your project. Similarly, the speed and rotation angle of the actuator should align with the desired motion parameters.

Mounting options are another important consideration. Different projects may require specific mounting configurations, such as flange or foot mounting. Ensuring compatibility between the actuator and your project's mounting requirements is essential.

Lastly, environmental considerations, such as temperature, humidity, and exposure to dust or chemicals, should be evaluated to select an actuator that can withstand the operating conditions of your project.

The Best Rotary Actuator in India

In the Indian market, there are several excellent rotary actuators available that can truly revolutionize your engineering projects. The best rotary actuator in India combines advanced features, high-quality materials, and robust construction to deliver exceptional performance and reliability.

These top-of-the-line rotary actuators offer precise control, smooth operation, and a wide range of torque capacities to cater to diverse project requirements. They are engineered to withstand rigorous conditions and provide consistent performance over an extended lifespan.

Positive customer reviews and testimonials further reinforce the reliability and effectiveness of the best rotary actuator in India. Customers praise the actuator's ability to improve productivity, reduce downtime, and enhance overall project efficiency.

Applications of Rotary Actuators in Engineering Projects

Rotary actuators find applications across various engineering domains. In robotics and automation, these actuators play a crucial role in providing controlled rotational movement to robotic arms, enabling precise manipulation of objects and intricate assembly processes.

Manufacturing and assembly lines heavily rely on rotary actuators for tasks such as part rotation, indexing, and sorting. The versatility and accuracy of these actuators enhance production efficiency and contribute to consistent product quality.

In the aerospace and defense sectors, rotary actuators are utilized in critical applications like aircraft control surfaces, missile guidance systems, and radar antenna positioning. The high reliability and performance of rotary actuators make them indispensable in ensuring safety and mission success.

Construction and infrastructure projects also benefit from rotary actuators, particularly in tasks involving heavy machinery, material handling, and complex mechanical systems. The ability to precisely control rotational movement greatly enhances operational efficiency and project outcomes.

How to Select the Right Rotary Actuator for Your Project

Selecting the right rotary actuator for your project can be a critical decision. To ensure the best fit, it is important to follow a systematic approach:

Assess your project requirements: Determine the specific motion and force parameters needed for your project. Consider factors like torque, speed, and mounting requirements.

Consult with experts or manufacturers: Seek advice from experienced professionals or manufacturers who specialize in rotary actuators. Their expertise can help you make an informed decision based on your project's unique needs.

Compare specifications and performance data: Analyze technical specifications, such as torque curves, speed-torque characteristics, and duty cycles. Compare different options to identify the actuator that aligns most closely with your project requirements.

Case Studies and Success Stories

Real-life examples provide valuable insights into the transformative impact of rotary actuators on engineering projects. One such case study involves a robotic automation project in the automotive industry. By incorporating high-quality rotary actuators, the company achieved faster cycle times, improved accuracy, and significant cost savings.

Another success story comes from the construction sector, where the adoption of rotary actuators revolutionized the operation of large cranes. The enhanced control and precision offered by these actuators increased safety, reduced downtime, and enabled smoother material handling, resulting in faster project completion.

Tips for Optimizing the Performance of Rotary Actuators

To maximize the performance and longevity of rotary actuators, certain best practices should be followed:

Regular maintenance and lubrication: Adhere to the manufacturer's maintenance guidelines, including periodic lubrication. This ensures smooth operation and extends the actuator's lifespan.

Proper installation and alignment: Ensure correct installation and alignment of the actuator to prevent excessive wear and premature failure. Follow the manufacturer's instructions for mounting and alignment procedures.

Monitoring and troubleshooting: Regularly monitor the actuator's performance and address any issues promptly. Timely troubleshooting can prevent costly breakdowns and minimize downtime.

Cost Considerations and Return on Investment

While cost is a significant factor in any engineering project, it is important to consider the long-term benefits and return on investment (ROI) offered by high-quality rotary actuators. Although premium actuators may have a higher upfront cost, their reliability, durability, and enhanced performance can result in substantial savings in terms of reduced maintenance, increased productivity, and improved project outcomes.

By investing in the best rotary actuator in India, you are equipping your engineering projects with a cutting-edge component that not only meets your immediate needs but also delivers long-term value.

Conclusion

Revolutionize your engineering projects with the best rotary actuator in India. These versatile and high-performance components provide precise control, compact design, and unmatched reliability. Whether it's robotics, manufacturing, aerospace, or construction, rotary actuators offer the power and flexibility needed to optimize project outcomes.

0 notes

Text

Power pack is a conventional power source that converts rotational energy to fluid power. The rotational energy is created by electric motors or engines powered by fuel. Dynamic Hydrofab’s power packs convert this energy which is then used for rotational or linear hydraulic actuators. Dynamic Hydrofab is the sole manufacturer and supplier of Hydraulic Cylinders. The type of Cylinders it offer includes Single acting Hydraulic Cylinders, Double acting Hydraulic Cylinders and many more. The company is well recognized as one of the prime manufacturer of Hydraulic Cylinders in India.

You can choose the options or even configure the pack for any kind of action or use. There are a wide variety of packs to choose from so that there is operating efficiency in your business and economy of scales. Made with superior quality and modern technologies, the hydraulic components are behind this pack’s success. With ease of installation and operation, these products are manufactured with international standards. Special care is being taken of the safety of the power pack with reduction in the noise level as well. The maintenance cost is very low, along with the horizontal arrangement of the electric motors and pumps for efficient and aligned coupling.

The power packs are made with materials that could withstand any kind of environment, be it Hostile or Harsh. The packs are engineered proficiently so that they can work without any hurdles for 24 straight hours. The materials used are water and tear resistant, manufactured at our own state-of-the-art manufacturing house.

0 notes

Text

A Solar-run reverse osmosis technique for top recovery of freshwater from saline groundwater

Desalination of groundwater is important in arid locations which can be distant from both equally seawater and freshwater assets. Appealing functions of a groundwater desalination program incorporate a large Restoration ratio, Procedure from the sustainable Strength supply like photo voltaic, and substantial water output per device of energy and land. Here we propose a new procedure that works by using a photo voltaic-Rankine cycle to drive reverse osmosis (RO). The Functioning fluid such as steam is expanded versus an influence piston that actuates a pump piston which in turn pressurises the saline water As a result passing it through RO membranes. A reciprocating crank mechanism is utilized to equalise the forces involving The 2 pistons. The choice of batch method in preference to ongoing move permits utmost Electricity Restoration and negligible concentration polarisation inside the vicinity on the RO membrane. This research analyses the sizing and effectiveness with the crank mechanism, quantifies Vitality losses from the RO separation and predicts the general overall performance. As an example, a program using a industry of linear Fresnel collectors occupying 1000 m2 of land and raising steam at 200 °C and 15.five bar could desalinate 350 m3/day from saline h2o that contains 5000 ppm of sodium chloride using a recovery ratio of 0.7.

Salinity of soil and groundwater is really a popular trouble taking place across all inhabited continents [one]. Significant parts of land lie previously mentioned brackish groundwater, especially in the earth's arid and semi-arid regions. From the absence of rain, desalination of groundwater will be the only way to offer freshwater for inland regions. Illustrations of countries the place groundwater desalination programs are now utilised consist of Australia, Egypt, India, Israel, Jordan, Morocco, the United Arab Emirates and The usa.

Just like seawater, the desalination of groundwater demands Electricity which is typically supplied from fossil gasoline sources. The need to fulfill the escalating desire for h2o, although minimizing the environmental affect connected to the usage of this kind of Power, causes it to be crucial to improve the effectiveness of the desalination approach also to get bigger benefit of renewable energies for example photo voltaic.

youtube

Lots of photo voltaic-pushed desalination technologies happen to be studied and a number of other are implemented [2]. Most drop into considered one of two types: (i) thermal distillation processes or (ii) non-thermal membrane separation procedures including electro-dialysis and reverse osmosis (RO). In the main group, solitary result photo voltaic stills can offer only a few litres of h2o for every square metre of captured sunlight on a daily basis even though various result photo voltaic stills might deliver tens of litres for each square metre [3].